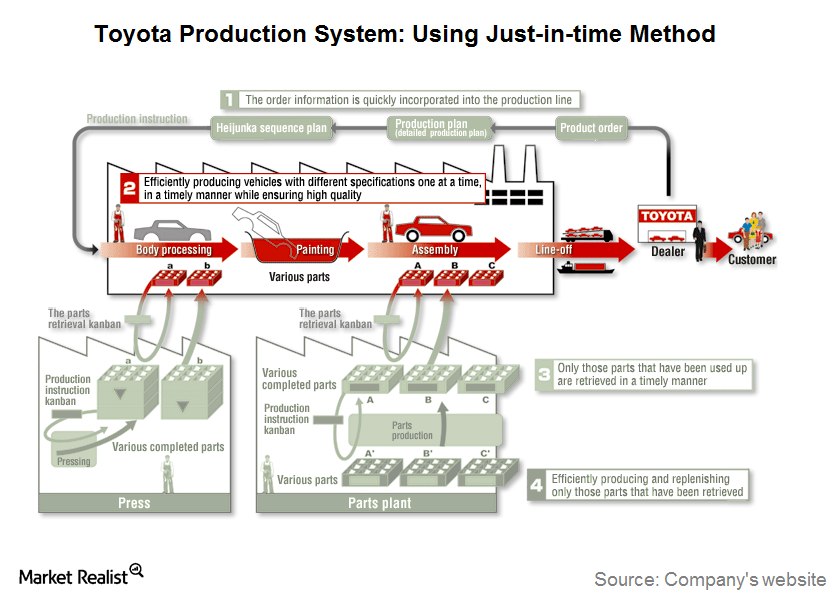

It takes a great deal of discipline to deploy and sustain a just in time system. It is much easier to have a stock pile of inventory but lots of carrying costs.

Just In Time By Toyota The Smartest Production System In The World – Youtube

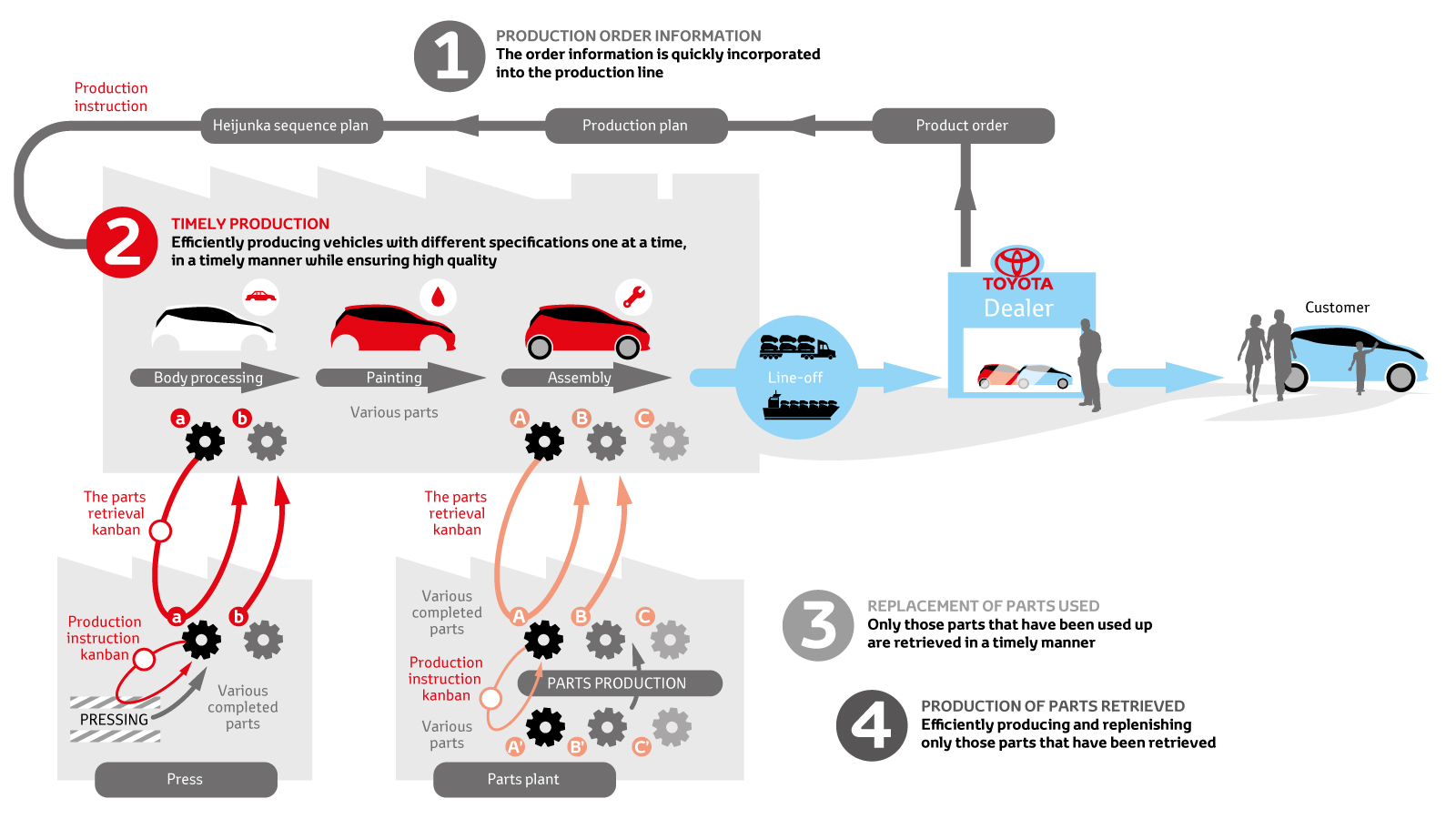

I believe that the most important thing is to ensure that there is neither shortage nor excess, that is, to ensure that there is no excess labor and time for the designated production.

Filme toyota just in time. El proposito principal de este sistema es eliminar. The company's success is mainly due to the implementation of the following: However, the true potential of this strategy was realized when it integrated this strategy with tps.

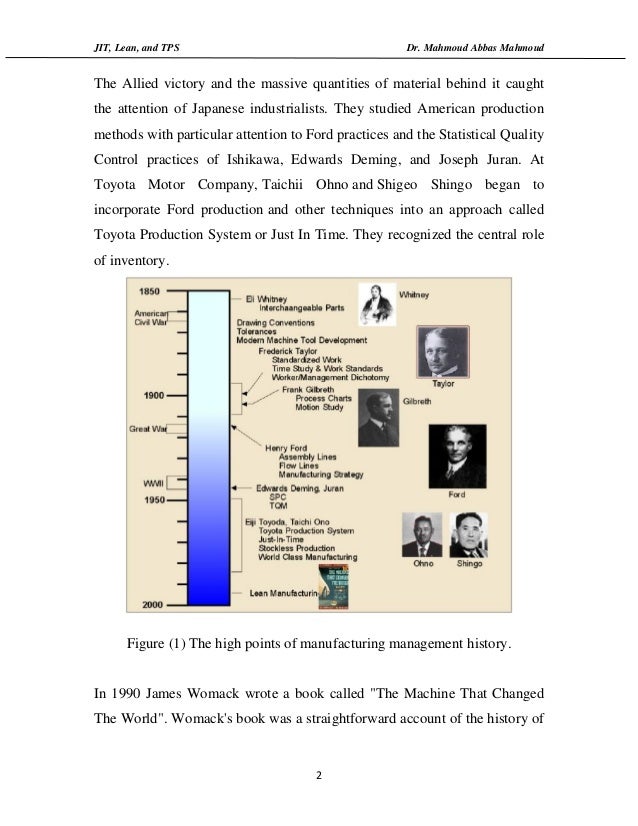

This philosophy was first developed and perfected within the toyota corporation by taiichi ohno as a means of meeting consumer demands with minimum delays. Employee satisfaction toyota production system makes use of the following vital elements: Superior technology and quality 4.

We will write a custom case study on just in time, toyota production systems and lean operations specifically for you. Still, in light of the disruptions from the. Just in time by toyota:

Suscríbete y dale like al inge.🏭⏰ jit | sistema de justo a tiempo toyota | just in t. The just in time (jit), toyota productions system (tps) and lean operations are some of the production systems used by different companies to improve operations and eliminate wastes. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods.

The smartest production system in the world. Just in time is critical to toyota’s success. La metodología 5s tiene por objetivo la creación de lugares de trabajo más organizados, ordenados, limpios y seguros.

There is no waste and there is no excess. The delta variant was spreading swiftly through the southeast asian nation. The time it takes toyota — renowned for its lean, “just in time” manufacturing system, to turn over its inventory increased by around 40% during the past 10 years, to 36.36 days as of march.

El sistema de producción y almacenamiento de toyota es un revolucionario sistema adoptado por las compañias japonesas después de la gran crisis petrolera de 1973. Seiji sugiura, a senior analyst at tokai tokyo research insititute, said toyota grew less efficient as it began stockpiling “chips and materials. Explicación simple sobre ¿qué rayos es jit?jueves de taller del inge.

I have written the page numbers in the braces from where these pictures were taken. About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. Lessons from ecamm’s leap into live streaming bootcamp;

Just In Time Jit Lean And Toyota Production System Tps

Just-in-time Manufacturing The Path To Efficiency

Suka Suka Kita Penerapan Just In Time Jit Pada Stretegy Toyota Guna Efisiensi Produksi

Toyota Production System Video Series – Part Three Just In Time – Youtube

What Is Jit Just In Time Manufacturing Why You Need It – Lean Factories

Just In Time Production Lean Production – Youtube

Tmmin Jit Dan Jidoka Sebagai Dua Pilar Utama Tps – Shift Indonesia

Penerapan Just In Time Toyota Pdf

Pdf Just In Time Jit Lean And Toyota Production System Tps

La Innovacion Just In Time In Toyota Production System

Toyota And Jit Management By Nick Varcoe

Just In Time Jit Lean And Toyota Production System Tps

Penerapan Just In Time Toyota Pdf

Why Toyotas Just-in-time Method Is Critical To Its Success